Machinery Alignment

Call Paisano Dimensional Control for Machinery Alignment

austin@paisanodc.com

Paisano Dimensional Control offers dimensional control (DimCon) surveys for commissioning hydrographic survey vessels of all kinds. We provide offset/lever arm surveys and calibrations for Gyro, IMU and DGPS systems against ground points using grid coordinates.

As standards in marine surveying get tighter, precision is paramount. Hydrographic survey vessels, responsible for mapping the seafloor, measuring water depths, and gathering data on submerged features, require precise tuning and alignment to ensure that their operations are accurate and reliable. Dimensional control surveys play a crucial role in establishing and maintaining the accuracy of data these vessels produce. These surveys ensure that the vessels’ physical structures, instruments, and positioning systems are aligned and calibrated to meet the rigorous standards of the hydrographic survey industry.

When commissioning of a new hydrographic survey vessels or changing/installing additional sensors it is vital to verify the exact position of each of these instruments relative to the vessel’s coordinate system based on the hull. Centerline of the vessel is established in dry dock from the keel or quayside from the wheelhouse or mast and the center stern. The Z plane is measured with points around the deck. All offsets are then relative to this coordinate system. This will ensure that the survey data collected will be as precise as possible and it greatly reduces the time necessary to complete GAMS and patch testing. DimCon also makes alongside nav checks and sea trials necessary to be completed much quicker to gain vessel acceptance from the client. This helps our customers bottom line by reducing overhead days before they can go on contract.

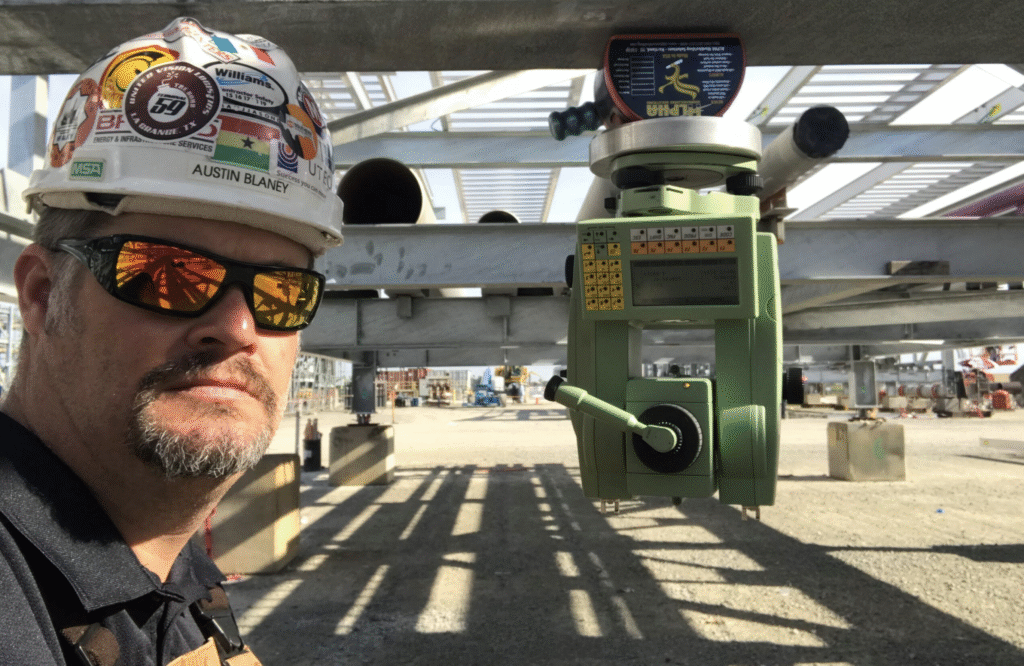

Using high precision 1 arc second Leica total stations with Spatial Analyzer metrology software, it allows us to work on the vessel quayside pitching, rolling and unleveled and still provide 1mm accurate feature offsets/lever arms in the same coordinate system. We use 4 – 6 GPS static control points on the dock to establish a network of grid coordinates that we use to carry out Gyro and DGPS verifications. Heading, Pitch and Roll verifications are completed with two total stations taking simultaneous shots synchronized to GPS UTC time so data can be compared to time stamps from vessel logs. In most instances we are able to provide all C-O corrections before we leave the vessel. Our goal is for the boat to go to work as soon as possible after we complete our scope of work for the DimCon vessel calibration.

Our experience ranges from drill ships all the way down to side scan tow fish. We can assist with all size boats, ROVs, AUVs, USVs, etc., whether quayside or in dry dock.

Paisano Dimensional Control uses precision survey equipment and metrology software to capture and interrogate data. Survey reports are provided to client and crane inspectors for review and we can assist with making adjustments and repairs as needed. We can also provide as-built surveys to record successful adjustments and provide a baseline for future survey reference.

Contact us to discuss details about your Machinery Alignment needs.

austin@paisanodc.com

Precision Machinery Alignment for DimCon and Hydrographic Surveys

In high-stakes environments where exactitude is non-negotiable, the alignment of critical machinery plays a foundational role in both safety and performance. Whether you’re overseeing a shipyard, a refinery, a heavy industrial facility, or a marine infrastructure project, precise machinery alignment isn’t just a technical detail—it’s a strategic advantage. When it comes to Dimensional Control (DimCon) and hydrographic survey applications, alignment isn’t guesswork. It’s precision engineering guided by data and proven methodology.

At Paisano Dimensional Control, we provide industry-specific alignment solutions designed to support complex DimCon surveys and hydrographic survey operations. If your project hinges on pinpoint accuracy, we’re ready to step in.

Why Machinery Alignment Matters in DimCon and Hydrographic Surveys

Dimensional Control surveys are often the invisible backbone of successful construction, engineering, and naval projects. Hydrographic surveys—dealing with underwater topography and infrastructure—demand an even more meticulous approach. Every millimeter counts when aligning assets, especially when integrated systems must perform seamlessly both above and below the surface.

Protecting High-Value Assets

Misalignment in rotating machinery or structural systems doesn’t just cause inefficiencies. It causes damage—often catastrophic. Poor alignment can lead to vibration, excessive wear, energy loss, shaft breakage, seal leaks, and premature equipment failure. In hydrographic survey operations, improper alignment of sonar transducers, navigation equipment, or mounting frames can produce inaccurate results or system downtime.

Aligning machinery during and after a DimCon survey ensures that operational equipment stays within design tolerances and functions reliably in high-stress environments.

Enhancing Data Accuracy

In hydrographic survey work, positional accuracy drives results. Survey vessels outfitted with multibeam echosounders, GPS systems, and motion sensors must be perfectly aligned to ensure that the data captured reflects true seafloor conditions. Any mechanical misalignment—however small—can introduce error across vast mapping areas.

DimCon services support the structural alignment of onboard machinery and fixed installations, reinforcing that all survey instruments function in harmony with the surrounding mechanical framework. This integration is vital to maintaining geospatial accuracy in subsea infrastructure assessments and bathymetric mapping.

Common Use Cases for Machinery Alignment in DimCon and Hydrographic Projects

Maritime and Shipyard Operations

In shipyards, machinery alignment plays a key role during vessel construction and repair. When propulsion systems, engines, shafts, or rudders are installed or adjusted, they must be precisely aligned to avoid torque imbalances and performance degradation. Dimensional Control ensures that these alignments conform to design specifications before vessels are launched.

Moreover, when hydrographic surveys are conducted for harbor expansions or navigational dredging, the onboard instruments must be precisely aligned with vessel frames to prevent discrepancies during mapping. This dual emphasis on DimCon and hydrographic performance makes alignment a shared priority.

Offshore Oil and Gas Facilities

For offshore rigs and platforms, accurate alignment is essential for rotating machinery such as pumps, compressors, and turbines. DimCon surveys are often used to validate construction tolerances during installation, but ongoing machinery alignment ensures that equipment runs optimally even under shifting loads and environmental conditions.

Hydrographic surveys are frequently used for subsea pipeline routing, jacket positioning, and underwater asset inspection. Aligning the data acquisition equipment with onboard machinery ensures that positional data remains consistent with structural and operational metrics.

Dams and Waterway Infrastructure

Machinery alignment in dam settings may involve massive rotating turbines, flood gates, or underwater sensors used in hydrographic assessments. Dimensional Control supports alignment of these elements relative to civil structures to avoid vibration, cavitation, and energy loss. Misalignment here doesn’t just affect equipment—it can compromise the safety of the entire system.

Hydrographic surveys also contribute to sediment buildup analysis, scour detection, and bathymetric updates. Precise machinery alignment ensures these tasks deliver the accuracy and reliability that engineers and regulators demand.

Key Equipment and Techniques Supporting Machinery Alignment

Modern machinery alignment, especially in the context of DimCon and hydrographic projects, demands advanced tools that offer real-time feedback and micrometer-level precision. Here’s what supports the Paisano Dimensional Control advantage:

Optical and Mechanical Tools

Tools like dial indicators, straightedges, and feeler gauges remain essential in tight-access environments. While not reliant on digital systems, these tools are indispensable in scenarios requiring tactile verification—particularly on legacy machinery or underwater mechanical structures.

Precision Levels and Autocollimators

In settings where angular deviation must be minimized, precision levels and autocollimators are used to align machinery relative to structural references or datum lines identified during a DimCon survey. These instruments provide high-resolution angular measurements critical for hydrographic sensor orientation or structural beam leveling.

Total Stations and Laser Trackers (Excluding Scanning)

Total stations and laser trackers are used for spatial measurement, but in this context, it’s important to note that Paisano Dimensional Control does not rely on laser scanning. Instead, these instruments are used to perform point-based verification, facilitating high-accuracy alignment across wide geometries without introducing laser scanning artifacts.

Hydrographic Sensor Mounting Systems

In marine settings, hydrographic survey equipment must be mounted with absolute consistency. Whether it’s a multibeam transducer, motion reference unit (MRU), or GPS antenna, misalignment during installation can produce compounded errors. Precision brackets and alignment jigs are employed to ensure accuracy and structural compliance across survey runs.

Challenges in Machinery Alignment for DimCon and Hydrographic Applications

Environmental Variability

Temperature fluctuations, tides, and vessel motion can all impact mechanical alignment. That’s why precision must be constantly verified—not just established at a single point in time. Dimensional Control practices address environmental variability by incorporating dynamic references and real-time validation.

Access Constraints

Whether working in confined shipboard compartments or submerged mechanical housings, access challenges can complicate alignment procedures. Paisano Dimensional Control is experienced in executing precision alignments in tight quarters, using a combination of mechanical tools, optical sighting, and custom fixturing.

Human Error and Legacy Systems

Machinery installed decades ago may not be compatible with modern digital alignment tools, and original design data may be missing or outdated. Our approach involves integrating real-time measurement systems with historical engineering data to reconcile old and new information, delivering alignment that is accurate, repeatable, and maintainable.

Machinery Alignment and Regulatory Compliance

Machinery alignment in marine and industrial environments is often subject to regulatory and certification oversight. In the U.S., this includes standards from the American Bureau of Shipping (ABS) (source) and Occupational Safety and Health Administration (OSHA) (source).

Dimensional Control ensures your equipment installations meet compliance requirements, while hydrographic survey accuracy contributes to certifications involving navigational safety, marine construction, and environmental impact assessments. Ensuring machinery is properly aligned with both standards and engineering expectations helps mitigate legal and operational risk.

Benefits of Choosing Paisano Dimensional Control for Machinery Alignment

Accuracy that Drives Performance

At Paisano Dimensional Control, we know the smallest misalignment can create the biggest delays. Our alignment solutions are grounded in engineering precision and dimensional data, whether you’re commissioning a new facility or retrofitting marine equipment. Our team translates complexity into confidence.

Cross-Disciplinary Expertise

We don’t just specialize in one aspect of alignment—we live at the intersection of marine surveys, heavy industrial controls, and civil construction. That means you get insights from across industries, applied directly to your alignment needs. We understand how machinery alignment influences hydrographic surveys, structural performance, and long-term maintenance demands.

Risk Reduction and Cost Control

Improper alignment causes premature wear and tear that leads to unscheduled downtime, repair costs, and energy waste. When your machinery is correctly aligned from the start—and maintained with data-backed precision—you extend equipment lifespan and gain operational predictability.

Responsive Support Across Project Phases

From feasibility studies and construction to maintenance and retrofit, we align our services with your project’s lifecycle. We are available when and where you need us, with scalable alignment solutions that meet evolving technical requirements.

What Sets Us Apart

We don’t rely on gimmicks or trends. We rely on sound engineering, real-world experience, and tools that deliver measurable accuracy. Paisano Dimensional Control focuses exclusively on point-based alignment and measurement—not laser scanning. That means less digital noise and more confidence in the data you rely on.

We’re proud to support industries where the stakes are high, and the margin for error is nonexistent.

Trust Paisano Dimensional Control for Machinery Alignment

When you need machinery alignment that supports your DimCon surveys and hydrographic survey goals, you need a team that understands both the science and the strategy behind it. At Paisano Dimensional Control, we align your systems with engineering accuracy, regulatory compliance, and operational integrity in mind.

Let us help you maintain the performance, reliability, and safety your project demands. When you need machinery alignment done right, call Paisano Dimensional Control—the partner trusted to keep your critical systems precisely on point.